Thoroughly remove all chips of the broken tap.

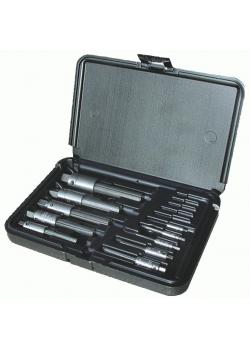

#TAP EXTRACTOR PROFESSIONAL#

With neatness derived from its use, the output has a professional look.You will be able to handle most of your extractions from a single set of tap extractors consisting of 5 or more sizes.

That’s why it’s important to take all the necessary precautions to avoid that situation. Removing a tap from a hole is not impossible, but the process can be time-consuming and not always successful. Unfortunately, this is also the less practical method as most small shops don’t have access to electrical discharge machines. The EDM will burn out the center of the tap leaving just the cutting edges stuck in the threads, which you can then pick out by hand. If you are planning to do it yourself, you can either use a 309 or 312 rod.ĮDM is probably the most reliable method to get the tap out of the hole. The process, as clearly explained by Jodie Collier of in the video below, consists of building up a head on top of the tap and then either grab it directly using vise grips or weld a nut on it. TIG welding is another practical way to remove the tap from the hole. You can purchase a set of Omegadrills on Ebay or through any premier distributor. This method is very effective, but it requires a very rigid setup. Omegadrills are uniquely shaped carbide drills, created specifically for removing broken taps. Most machinist have cold chisels and punches in their toolbox, but in case you are considering purchasing a new set, this 16-pieces set from Amazon is what we recommend. You can break the piece using a cold chisel, in case part of broken tap is above the surface, and then complete the job using a center punch. This method is the most cost-effective, but also the least effective. But how? Here are several different methods to get the job done. Since scrapping the part should always be your last resort, you’ll have to figure out a way to get that piece of metal out of the cavity. The broken tap is inside the hole and you only have two options: get it out or scrap the part. Why did this happen? Not enough cutting fluid? Poor chip control? There are plenty of factors that can cause tap breakage, but at this point they are irrelevant.

You select the right tap, start working on the hole, and then suddenly, SNAP! and the tap is broken inside the hole. We’ve all been in this situation: You are working on a part with internal threads.

0 kommentar(er)

0 kommentar(er)